Frequently Asked Questions

![]()

The

"PULSE MON"

test

point gives users the ability to observe a signal

resulting from a neutron or gamma event after it has been

amplified and appropriate wave shaping applied. The

amplified pulse, as measured from the detector, provides

users with a method to observe and monitor the signal

without affecting the performance of the system. The

output impedance of the signal at the

"PULSE

MON"

test point is 50 ohms (about 10kHz),

but capacitively coupled. Applications requiring analog

signal monitoring rather than the TTL OUT signal will

work well with this test point. The signal at the

"PULSE

MON"

can be substituted for the

"TTL

OUT"

if that suits your applications needs

better. Yes, the

"PULSE MON"

test

point is available on each of the PDT100A, PDT110A, and

PDT120A modules.

The

"PULSE MON"

test

point gives users the ability to observe a signal

resulting from a neutron or gamma event after it has been

amplified and appropriate wave shaping applied. The

amplified pulse, as measured from the detector, provides

users with a method to observe and monitor the signal

without affecting the performance of the system. The

output impedance of the signal at the

"PULSE

MON"

test point is 50 ohms (about 10kHz),

but capacitively coupled. Applications requiring analog

signal monitoring rather than the TTL OUT signal will

work well with this test point. The signal at the

"PULSE

MON"

can be substituted for the

"TTL

OUT"

if that suits your applications needs

better. Yes, the

"PULSE MON"

test

point is available on each of the PDT100A, PDT110A, and

PDT120A modules.

and if so, how long?

![]() Each

of the PDT100A, PDT110A, PDT120A and PDT210 products has

a

TTL OUT

signal designed with an internal

50-ohm transmission line driver. Instruments are factory

tested using a 100 meter cable. In some applications,

customers have used these products with cable lengths in

excess of 300 meters with good results.

Each

of the PDT100A, PDT110A, PDT120A and PDT210 products has

a

TTL OUT

signal designed with an internal

50-ohm transmission line driver. Instruments are factory

tested using a 100 meter cable. In some applications,

customers have used these products with cable lengths in

excess of 300 meters with good results.

in high radiation fields?

![]() Our product line has been designed to operate in

high radiation fields. The PDT110A has been tested in

radiation fields in excess of 1Mrad without failure.

Our product line has been designed to operate in

high radiation fields. The PDT110A has been tested in

radiation fields in excess of 1Mrad without failure.

the PDT110A and the PDT120A. Which one should be

used for my application?

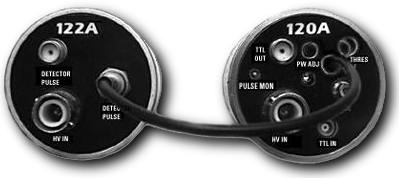

![]() The PDT120A module

performs all of the functions of a PDT110A but also

contains an integral cable that is used only to monitor

additional detectors by using the PDT122A support module.

The integral attached cable on the PDT120 connects

directly to the

PULSE MON

connector of the

PDT122A. The PDT120A/PDT122A combination exists only to

provide users with a viable lower cost solution for

applications that require the monitoring of many

detectors.

The PDT120A module

performs all of the functions of a PDT110A but also

contains an integral cable that is used only to monitor

additional detectors by using the PDT122A support module.

The integral attached cable on the PDT120 connects

directly to the

PULSE MON

connector of the

PDT122A. The PDT120A/PDT122A combination exists only to

provide users with a viable lower cost solution for

applications that require the monitoring of many

detectors.

As an example, suppose you have an application that requires monitoring of thirty-six detectors. Using PDT110A modules, thirty-six modules are required. However, for each PDT120A that is used, generally two PDT122A support modules are used. (Note: Depending on your application, three or four PDT122A may be used for each PDT120A.) For a system requiring thirty-six detectors, twelve PDT122A modules and twenty-four PDT122A's support modules would be used. This has the advantage of simplifying the cable setup, including the cable routing and power supply current requirements. The PDT122A contains only passive components, therefore a power cable is not required.

The PDT122A is substantially lower in cost than a PDT110A. Another advantage, since the PDT122A contains only passive components, is improved resistance to radiation effects.

The disadvantage of the PDT120A/PDT122A combination is its effect on amplifier sensitivity. The PDT122A capacitively loads the PDT120A preamplifier. As PDT122A modules are added, the sensitivity of the PDT120A can be increased by changing the "THRES ADJ" trimpot. For applications requiring the highest sensitivity, the PDT120A/PDT122A could be a disadvantage.

To summarize, for application requiring many detectors, the PDT120A/PDT122A configuration is a cost-effective solution that simplifies your system cabling demands. However, for applications where only a few detectors are used and the highest sensitivity is required, the PDT110A is the answer.

![]()

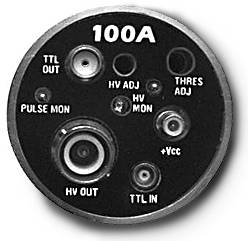

The bias supply is designed to be adjusted via

an internal 12-turn trimpot or by application of an

external dc voltage for use with remote applications. The

voltage range is specified at 0 volts to 2200 volts. The

output current should not exceed 100µA. The bias supply

is designed to bias detectors only and is not designed to

support currents in excess of 50 µA.

The bias supply is designed to be adjusted via

an internal 12-turn trimpot or by application of an

external dc voltage for use with remote applications. The

voltage range is specified at 0 volts to 2200 volts. The

output current should not exceed 100µA. The bias supply

is designed to bias detectors only and is not designed to

support currents in excess of 50 µA.

The PDT100A contains a "HV OUT" SHV connector for use as an external bias supply for interfacing to PDT110A, PDT120A/PDT122A modules, and other detector bias needs.

![]() This problem could very likely be a power supply

problem. Remember, with no counts, a PDT110 requires

about 30mA from the power supply. At 100k counts, the

supply requirement is about 40mA. For counts in excess of

100k, the supply load requirement remains at about 42mA.

RG176 coaxial cable has a resistance of about .32 ohms

per meter. If you are using ten PDT110 instruments

running at a high count level, your supply current for

the system will be about .4 amps. If your power supply

cable is 20 meters, the cable resistance will be 6.4

ohms. A voltage drop of 2.56 volts [(6.4ohms X .4

amps)=2.56 volts] will occur from the supply source to

the PDT instruments. If you are using PDT110A's that

operate on +5volts, the voltage at the amplifier will be

2.34 volts, which is below the power supply

specification. To alleviate this problem, you can use

PDT110A instruments that are designed for +12V operation.

Twelve-volt PDT110A's require less supply current, and

operate over a supply range of 9 volts to 15 volts. If

you are using PDT110A's that require a +5 volt supply,

you must either reduce or eliminate the cable resistance,

or increase the power supply voltage at the source until

the PDT110A instruments receive the correct voltage.

This problem could very likely be a power supply

problem. Remember, with no counts, a PDT110 requires

about 30mA from the power supply. At 100k counts, the

supply requirement is about 40mA. For counts in excess of

100k, the supply load requirement remains at about 42mA.

RG176 coaxial cable has a resistance of about .32 ohms

per meter. If you are using ten PDT110 instruments

running at a high count level, your supply current for

the system will be about .4 amps. If your power supply

cable is 20 meters, the cable resistance will be 6.4

ohms. A voltage drop of 2.56 volts [(6.4ohms X .4

amps)=2.56 volts] will occur from the supply source to

the PDT instruments. If you are using PDT110A's that

operate on +5volts, the voltage at the amplifier will be

2.34 volts, which is below the power supply

specification. To alleviate this problem, you can use

PDT110A instruments that are designed for +12V operation.

Twelve-volt PDT110A's require less supply current, and

operate over a supply range of 9 volts to 15 volts. If

you are using PDT110A's that require a +5 volt supply,

you must either reduce or eliminate the cable resistance,

or increase the power supply voltage at the source until

the PDT110A instruments receive the correct voltage.

![]() The PDT110A instruments are shipped from the

factory with a 50nS "TTL OUT" pulse setting.

The 50nS pulse width can be increased by changing the

trimpot setting. A single-turn trimpot is located just

beneath the hole labeled "PW ADJ." A 50nS pulse

width is not recommended for long cable length. The

"TTL OUT" signal is produced using a 50-ohm

driver that is expecting to see a 50-ohm terminator.

Although it is not necessary, if the 50-ohm coaxial cable

is properly terminated, reflections will be prevented and

the possibility of double pulse counting will be

eliminated. A terminated cable will also help prevent

phase delay problems. If the cable length is less than 15

meters, a cable termination will likely not be required.

When the cable is terminated, the magnitude of the pulse

will be reduced. However, the spectral purity will be

greatly improved, and the pulse will still look like a

pulse, with good rise and fall times.

The PDT110A instruments are shipped from the

factory with a 50nS "TTL OUT" pulse setting.

The 50nS pulse width can be increased by changing the

trimpot setting. A single-turn trimpot is located just

beneath the hole labeled "PW ADJ." A 50nS pulse

width is not recommended for long cable length. The

"TTL OUT" signal is produced using a 50-ohm

driver that is expecting to see a 50-ohm terminator.

Although it is not necessary, if the 50-ohm coaxial cable

is properly terminated, reflections will be prevented and

the possibility of double pulse counting will be

eliminated. A terminated cable will also help prevent

phase delay problems. If the cable length is less than 15

meters, a cable termination will likely not be required.

When the cable is terminated, the magnitude of the pulse

will be reduced. However, the spectral purity will be

greatly improved, and the pulse will still look like a

pulse, with good rise and fall times.

![]() PDT110A instruments have been tested with

several detector types. Since the bias supply and

sensitivity are indirectly related, a lower bias supply

will require a higher amplifier sensitivity. The best

procedure is to set the sensitivity to about 0.04pC (the

factory setting) and adjust the bias voltage until a good

plateau is achieved. For .05pC, a good plateau is

typically achieved at a bias voltage of 1800-1850 volts.

To increase the sensitivity of PDT instruments, turn the

"THRES

ADJ"

trimpot (a 12-turn

PDT110A instruments have been tested with

several detector types. Since the bias supply and

sensitivity are indirectly related, a lower bias supply

will require a higher amplifier sensitivity. The best

procedure is to set the sensitivity to about 0.04pC (the

factory setting) and adjust the bias voltage until a good

plateau is achieved. For .05pC, a good plateau is

typically achieved at a bias voltage of 1800-1850 volts.

To increase the sensitivity of PDT instruments, turn the

"THRES

ADJ"

trimpot (a 12-turn

trimpot) clockwise. To optimize the sensitivity,

set the sensitivity about midscale. If you're not sure,

set it at approximately six turns below maximum (maximum

is turned all the way clockwise). Then sweep the bias

voltage, looking for a plateau. Increase the sensitivity,

and look again for an improved plateau. Continue doing so

until an improved plateau is found. Typically, the

factory setting is quite good for a bias voltage of about

1800 volts using He3 detectors. This will vary greatly,

however, depending on the detector gain and type of

detector.

trimpot) clockwise. To optimize the sensitivity,

set the sensitivity about midscale. If you're not sure,

set it at approximately six turns below maximum (maximum

is turned all the way clockwise). Then sweep the bias

voltage, looking for a plateau. Increase the sensitivity,

and look again for an improved plateau. Continue doing so

until an improved plateau is found. Typically, the

factory setting is quite good for a bias voltage of about

1800 volts using He3 detectors. This will vary greatly,

however, depending on the detector gain and type of

detector.

![]() If you tighten any of the connectors on a

PDT110A, PDT120A or PDT100A instrument with a wrench, you

will most likely damage the connector solder connections.

These connectors will operate quite satisfactorily with

hand tightening. Excessive torque on the connector will

break the connector leads soldered into the printed

circuit board. The connector leads are gold plated brass

and are easily damaged with only a little torque applied.

If you tighten any of the connectors on a

PDT110A, PDT120A or PDT100A instrument with a wrench, you

will most likely damage the connector solder connections.

These connectors will operate quite satisfactorily with

hand tightening. Excessive torque on the connector will

break the connector leads soldered into the printed

circuit board. The connector leads are gold plated brass

and are easily damaged with only a little torque applied.

Products | Features | Dimensions | FAQ's | Warnings | Contact Us | Home

Copyright 2000-2022,

Precision Data Technology, Inc. All Rights Reserved

Designed by

Spidernet

and Maintained by

Tim Eccleston